Hollow metal doors are vital in many construction projects. They offer security, durability, and fire resistance.

For Saudi contractors, understanding the details of hollow metal doors is crucial. These doors are not just about providing entry and exit points; they play a significant role in the overall safety and functionality of a building. Knowing the specifics can help contractors choose the right door for each project.

This guide will cover essential aspects like materials, installation, and maintenance. It aims to give contractors the knowledge they need to make informed decisions. Whether you are new to the field or looking to refresh your knowledge, this guide will be a valuable resource. Read on to learn more about the intricacies of hollow metal doors.

Introduction To Hollow Metal Doors

Hollow metal doors are a staple in construction. They are known for their durability and strength. For Saudi contractors, understanding the details of these doors is essential. This guide will provide a comprehensive overview.

Importance In Construction

Hollow metal doors play a crucial role in construction projects. They offer unparalleled security and longevity. These doors are resistant to fire, which enhances safety. They also provide sound insulation, making them ideal for various environments.

Moreover, they are customizable. Contractors can choose from different finishes and designs. This makes them versatile for any architectural style. The doors are also easy to maintain, reducing long-term costs.

Types And Applications

There are several types of hollow metal doors. Each type serves a unique purpose. Understanding their applications is key for contractors.

- Flush Doors: These are smooth and flat. They are ideal for interior use.

- Panel Doors: These doors have raised panels. They add a decorative touch.

- Fire-Rated Doors: These doors can withstand fire for a specific period. They are crucial for safety in commercial buildings.

- Stainless Steel Doors: These are used in high-traffic areas. They are corrosion-resistant and very durable.

The applications of hollow metal doors are vast:

- Commercial buildings

- Industrial facilities

- Educational institutions

- Healthcare facilities

Each type of door has its specific use. Understanding these applications helps in selecting the right door for the project.

| Type | Application |

|---|---|

| Flush Doors | Interior use |

| Panel Doors | Decorative interior use |

| Fire-Rated Doors | Commercial buildings |

| Stainless Steel Doors | High-traffic areas |

Credit: www.facebook.com

Materials And Specifications

Understanding the materials and specifications of hollow metal doors is crucial for Saudi contractors. These details determine the door’s strength, durability, and suitability for different environments. Let’s explore the common materials used and the standard specifications.

Common Materials Used

Hollow metal doors are typically made from two main materials. These materials are steel and stainless steel. Steel doors are the most common due to their strength and affordability. Stainless steel doors are preferred for their corrosion resistance. They are ideal for coastal or industrial areas.

Here is a table showing the key differences:

| Material | Characteristics |

|---|---|

| Steel | Strong, affordable, requires regular maintenance |

| Stainless Steel | Corrosion-resistant, ideal for harsh environments, more expensive |

Choosing the right material depends on the specific needs of the project.

Standard Specifications

Standard specifications for hollow metal doors ensure consistency in quality and performance. Key specifications include:

- Thickness: Commonly 1.75 inches, but can vary based on security needs.

- Gauge: Gauge indicates the thickness of the steel. Lower gauge numbers mean thicker steel. Typical gauges are 18, 16, and 14.

- Core: The core can be honeycomb, polystyrene, or steel stiffened. Each offers different levels of insulation and strength.

- Fire Rating: Doors can be rated for 20, 45, 60, or 90 minutes to meet fire safety requirements.

Contractors should refer to these specifications to select the best door for their project. Proper selection ensures safety, durability, and compliance with building codes.

Design And Manufacturing

Understanding the details of hollow metal doors is crucial for Saudi contractors. One important aspect is the design and manufacturing process. This section breaks down the key considerations and steps involved in creating high-quality hollow metal doors.

Design Considerations

Designing hollow metal doors involves several key factors:

- Material Selection: Choose between steel, stainless steel, or galvanized steel.

- Thickness: Standard thickness ranges from 18 to 12 gauge.

- Fire Rating: Determine the required fire-resistance rating.

- Security Features: Consider adding reinforcements or bulletproof options.

- Insulation: Decide on the type of core material for insulation.

Manufacturing Process

The manufacturing of hollow metal doors typically includes these steps:

- Sheet Cutting: Metal sheets are cut to the required size.

- Forming: Sheets are formed into the door shape using press brakes.

- Welding: Corners and seams are welded for strength.

- Surface Treatment: Doors undergo cleaning, priming, and painting.

- Assembly: Hinges, locks, and other hardware are installed.

- Quality Control: Doors are inspected for defects and compliance.

Here is a table summarizing the key steps in the manufacturing process:

| Step | Description |

|---|---|

| Sheet Cutting | Cutting metal sheets to the required size. |

| Forming | Forming sheets into door shapes using press brakes. |

| Welding | Welding corners and seams for strength. |

| Surface Treatment | Cleaning, priming, and painting the doors. |

| Assembly | Installing hinges, locks, and other hardware. |

| Quality Control | Inspecting doors for defects and compliance. |

Credit: www.ul.com

Installation Guidelines

Understanding the installation guidelines for hollow metal doors is crucial. Proper installation ensures durability and security. This section will cover key steps to follow. From pre-installation requirements to a detailed step-by-step process. Let’s dive into the essentials.

Pre-installation Requirements

Before installation, gather all necessary tools and materials. Ensure you have the correct door size and frame. Verify that the door and frame match the specifications. Check the installation site for any obstructions. Make sure the floor is level and the walls are plumb. Prepare the opening to the required dimensions.

Inspect the door and frame for any damage. Ensure all components are in good condition. Verify that you have all hardware and accessories. This includes hinges, locks, and fasteners. Lay out all parts to ensure nothing is missing.

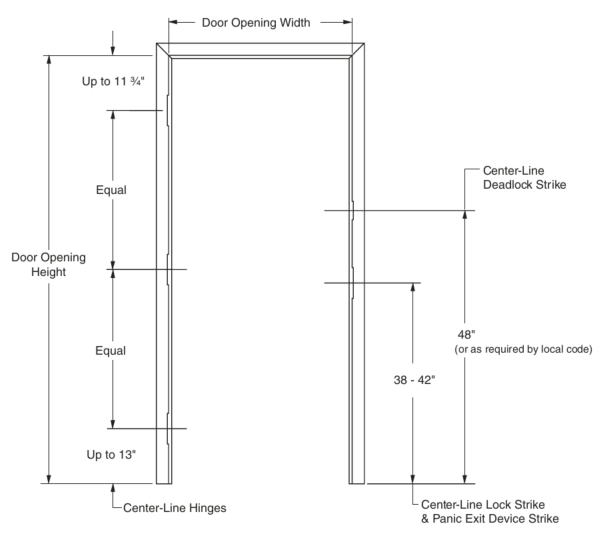

Step-by-step Installation

First, position the frame in the opening. Use shims to align the frame. Ensure it is level and plumb. Secure the frame temporarily with screws. Double-check alignment before proceeding.

Next, prepare the door for hanging. Attach the hinges to the door. Position the door within the frame. Ensure proper clearance on all sides. Secure the hinges to the frame. Check the door swings freely and closes properly.

Install the lockset and other hardware. Follow manufacturer instructions for proper placement. Ensure all components are secure. Test the lockset for smooth operation. Adjust as necessary for proper fit.

Finally, seal the perimeter of the frame. Use caulk or weatherstripping as needed. Ensure there are no gaps. This will prevent drafts and improve security. Clean the area and remove any debris.

Congratulations, the installation is complete. Perform a final inspection. Ensure everything is secure and functioning properly. Your hollow metal door is now ready for use.

Performance And Durability

Understanding the performance and durability of hollow metal doors is crucial for Saudi contractors. These doors are commonly used in various settings due to their strength and long-lasting nature. This section delves into the key aspects that ensure these doors meet rigorous standards and maintain their quality over time.

Testing Standards

Hollow metal doors must undergo several tests to ensure they meet performance standards. These tests assess the door’s resistance to fire, impact, and extreme weather conditions. Here are some of the common testing standards:

- Fire Resistance: Ensures the door can withstand high temperatures for a specified period.

- Impact Resistance: Tests the door’s ability to endure physical impacts without damage.

- Weather Resistance: Evaluates the door’s performance under harsh weather conditions, including rain and extreme heat.

Meeting these standards guarantees that the doors provide safety and reliability in various environments.

Longevity And Maintenance

The longevity of hollow metal doors is one of their most attractive features. Made from high-quality steel, these doors can last for decades with proper maintenance. To ensure their durability, regular maintenance is necessary:

- Regular Cleaning: Clean the doors with mild detergent and water to remove dirt and debris.

- Lubrication: Apply lubricant to hinges and locks to prevent rust and ensure smooth operation.

- Inspections: Conduct periodic inspections to check for any signs of wear and tear.

By following these steps, contractors can ensure that hollow metal doors remain in excellent condition, providing security and durability for many years.

| Maintenance Task | Frequency |

|---|---|

| Cleaning | Monthly |

| Lubrication | Quarterly |

| Inspections | Annually |

Adhering to these guidelines helps in maximizing the lifespan and performance of hollow metal doors, making them a reliable choice for various applications.

Credit: special-lite.com

Compliance And Regulations

Understanding compliance and regulations is crucial for Saudi contractors working with hollow metal doors. Knowledge of local building codes and international standards ensures safety and quality. This guide will help navigate the key aspects of compliance.

Local Building Codes

Saudi Arabia has specific building codes for construction projects. These codes ensure structural safety, fire resistance, and accessibility. Contractors must adhere to these regulations to avoid penalties and ensure project approval.

Compliance with local codes also guarantees that the doors meet the required performance standards. This includes durability, strength, and weather resistance. Regular updates to the codes mean contractors need to stay informed to maintain compliance.

International Standards

International standards play a significant role in the construction industry. Standards such as ISO and ANSI provide guidelines for manufacturing and installation. These standards ensure consistency and quality across projects.

Adhering to international standards helps in achieving global recognition and reliability. It also ensures that the hollow metal doors are safe and functional. Contractors should familiarize themselves with these standards to ensure their projects meet global benchmarks.

Challenges And Solutions

Understanding the details of hollow metal doors can be tough for Saudi contractors. These doors offer durability and security but come with their own set of challenges. This section will address common issues and provide effective solutions to these challenges.

Common Issues

Hollow metal doors face several common issues that contractors need to address:

- Corrosion: The metal can rust over time, especially in humid environments.

- Installation Errors: Poor installation can lead to misalignment and functional issues.

- Lock Malfunctions: Locks may not fit correctly, leading to security concerns.

- Paint Peeling: Exposure to weather can cause paint to peel off.

- Insulation Problems: Improper insulation can affect energy efficiency.

Effective Solutions

Implementing the right solutions can mitigate these issues:

- Anti-Corrosion Treatments: Apply rust-resistant coatings to prevent corrosion.

- Professional Installation: Ensure skilled technicians handle the installation process.

- High-Quality Locks: Use locks designed specifically for hollow metal doors.

- Weather-Resistant Paint: Choose paint that can withstand extreme weather conditions.

- Proper Insulation: Use high-quality insulation materials to improve energy efficiency.

| Issue | Solution |

|---|---|

| Corrosion | Anti-Corrosion Treatments |

| Installation Errors | Professional Installation |

| Lock Malfunctions | High-Quality Locks |

| Paint Peeling | Weather-Resistant Paint |

| Insulation Problems | Proper Insulation |

Understanding these challenges and implementing solutions can make a significant difference. It ensures that hollow metal doors are both functional and durable.

Cost Considerations

Understanding the cost considerations of hollow metal doors is crucial for Saudi contractors. Budgeting and analyzing the cost-benefit ratio can help you make informed decisions. This section will cover essential tips for budgeting and performing a cost-benefit analysis.

Budgeting Tips

Start by estimating the total number of doors needed for the project. Account for both interior and exterior doors. Next, compare prices from different suppliers. This will help you find the best deals. Consider bulk purchasing for potential discounts. Don’t forget to include installation costs in your budget. Always set aside a contingency fund. This can cover unexpected expenses.

Cost-benefit Analysis

Evaluate the long-term benefits of hollow metal doors. These doors offer durability and security. They require less maintenance compared to wooden doors. This can save money over time. Consider the energy efficiency of these doors. They provide better insulation. This can reduce heating and cooling costs. Weigh these benefits against the initial cost. This will give you a clearer picture of the investment’s value.

Future Trends

Future trends in hollow metal doors are shaping the construction industry in Saudi Arabia. New designs and sustainable practices are leading this change. These trends promise better efficiency and eco-friendliness.

Innovations In Design

Modern hollow metal doors feature cutting-edge designs. These designs offer better security and aesthetic appeal. Contractors can find doors with sleek, minimalistic looks. Smart technology integration is another innovation. This includes features like biometric locks and remote access.

Fire-rated doors are also becoming popular. They provide safety and meet regulatory standards. Acoustic doors help reduce noise in busy areas. These design innovations cater to various needs and preferences.

Sustainability Practices

Sustainable construction is crucial for the future. Hollow metal doors are now more eco-friendly. Recycled materials are often used in their production. This reduces waste and conserves resources.

Energy efficiency is another focus. Insulated doors help maintain indoor temperatures. This lowers energy costs and improves comfort. Long-lasting materials ensure durability and less frequent replacements. Sustainable practices benefit both the environment and the economy.

Frequently Asked Questions

What Are Hollow Metal Doors?

Hollow metal doors are durable and secure doors made from steel. They are ideal for commercial and industrial applications. Contractors prefer them for their strength and longevity.

Why Use Hollow Metal Doors In Saudi Arabia?

Hollow metal doors withstand extreme temperatures and harsh conditions. They provide excellent security and durability. They are also fire-resistant, making them a safe choice for buildings.

How Are Hollow Metal Doors Installed?

Hollow metal doors are installed by attaching them to a metal frame. Proper alignment ensures smooth operation. Professional installation is recommended for optimal performance and security.

What Are The Benefits Of Hollow Metal Doors?

Hollow metal doors offer superior strength, security, and fire resistance. They are also low maintenance and long-lasting. Their durability makes them cost-effective in the long run.

Conclusion

Understanding hollow metal door details is crucial for Saudi contractors. This guide offered essential insights. Armed with this knowledge, you can make informed decisions. Choose the right materials and designs. Enhance safety and functionality in every project. Stay updated on industry standards.

Keep your construction projects top-notch. Thank you for reading.